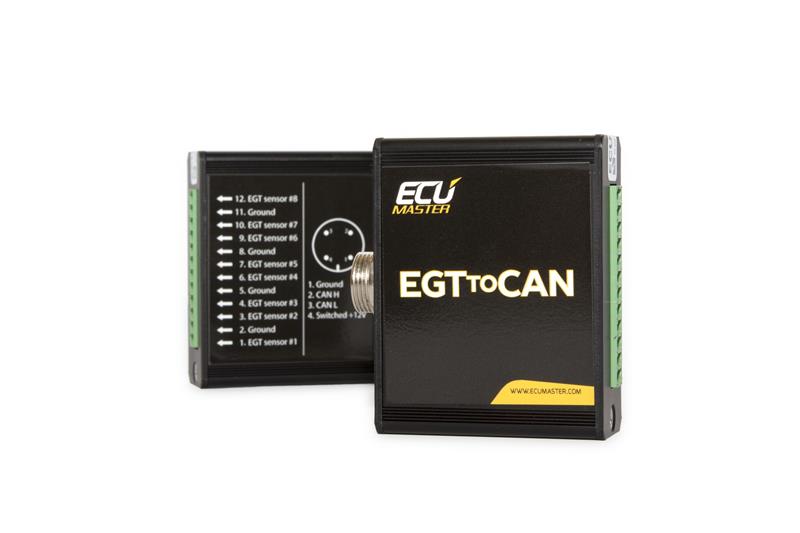

EGT to CAN 8ch

Website productcategorie |

Accessoires , Accessoires |

Interne referentie |

3S2EGT0007 |

The EGT to CAN module collects input signals from 8 EGT probes (K-Type thermocouples), converts the probe voltage into a numerical temperature figure and sends the appropriate data via a CAN bus. The module is fully configurable using USB connection and Microsoft Windows based client software. High quality EGT sensors are available on request.

Using ECUMASTER EMU engine management it is possible to trim each cylinder fuel dose based on EGT temperatures readings.

Up to 8 EGT probes,

Cold junction compensation

0-1250C input range

CAN 2.0 compatible

Configurable CAN bitrate, byte order (Intel, Motorola), message IDs

USB port for PC connection

Client software for configuration and temperature monitoring

wat zit in de doos?

1x Ecumaster EGT to CAN Module

1x Cabel AA

1x Connector NC/4P-514

https://www.ecumaster.com/products/egt-to-can/